How to cut Sheet Metal?

What is Sheet Metal?

Sheet metal is metal formed through an industrial process into thin, flat pieces, allowing it to be used for a variety of roles and projects. As such, it is fundamental to metal working, and here at the London Metal Store, we offer a wide range of metal sheets that can suit your requirements, whatever they may be.

We are one of the leading metal supply stores in the UK, and as such, you’ll find a huge selection of options here on our website for you to explore. You can also get in touch with us if you have specific requirements you’d like us to meet.

Contact us today to find out more about how we can help you with your sheet metal project.

How to cut metal with a guillotine?

Guillotines are the most common way to cut sheet metal. The machines are used to cut the metal in different sizes, dimensions and scales accurately. Guillotines are very efficient which means turnaround times are faster.

Steps

- Put on eye and ear protection as well as gloves.

- Change settings to fit your desired shear angle, rake angle and length of cut.

- Make sure guards are in correct place and isolated from blades and clamps. Do not use any elements that aren't fit for the guillotine.

- Put metal into machine and make sure it touches the back before enforcing the clamps to keep the metal in place.

- Pull leaver so that the blade begins to shear off the metal.

- Once completed, the metal should drop out of the machine, do not try to do yourself if this doesn't happen, call an engineer.

How can I use a waterjet to cut through sheet metal?

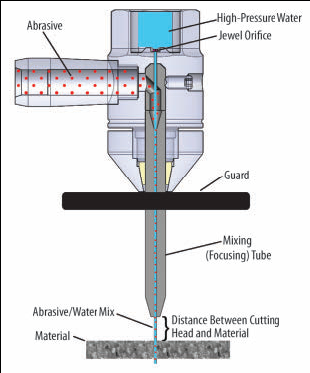

Waterjet cutting is when a high pressure of water is applied to cut through metal. It is channelled through a very narrow nozzle to improve the accuracy of the cut. Waterjets can cut through many different metals such as aluminium, copper, stainless steel and more. Waterjets are beneficial as the water protects any burn marks or cracking from being incurred on the metal.

How to laser cut sheet metal?

Laser cutting is when a high powered laser is used to shape a material or metal. When cutting metal you can either use fiber lasers or a neodymium lasers. Laser cutting is perfect for sheet metal due to it's high precision when cutting. Laser cutting is a very efficient process that causes minimal damage to sheet metal. Laser cutting also consumes low energy which means it's also cost effective.

Steps

- Put image of metal you are trying to cut into design software.

- Set dimensions of image to match size of metal piece.

- Indicate on software where you are cutting your metal.

- Place metal piece in centre of laser cutting mat.

- Clean lens of the laser cutter with alcohol.

- Adjust lens height to preferred fit.

- Make sure fume extractor is turned on.

- Select either Vector print (for cutting) or Raster print (for engraving).

- Press print and you should be left with your desired metal cut.

How to punch sheet metal?

Metal punching these days is carried out by a modern day punching machine. There are lots of different punching machines but the majority follow this process.

Steps

- Put on eye and ear protection

- Put the sheet metal in between the punch and die.

- The punch will move downwards into the die forming the punch in the sheet.

- Recycle the any collected cut metal.

- Repeat steps to create your preferred shape.

Make sure that the punch and die are in good condition to ensure clean punches. It's important to note that the thicker the metal the harder it is to punch neat holes. Harder metals also need to be punched with more force.

How to cut sheet metal using a grinder?

Angle grinders are one of the most popular cutting tools. It is important that when cutting that you turn slowly to avoid damage or injury.

Steps

- Put on ear and eye protection and then make sure you have a C clamp and metal cut-off disc.

- Attach metal cut-off disc to grinder.

- Use permanent marker to indicate where you are cutting on metal piece.

- Start cutting metal whilst holding grinder with both hands, make sure you follow your marker.

See more blog posts here